Factories once echoed with the manual packing noise, slow and tiring. Today, quiet robots dominate lines. Automation now decides speed, safety, and output. Packaging is no longer just end-of-line work. It shapes profitability. This article explores how Robotic Case Packaging Systems and intelligent automation transform production environments, focusing on accuracy, adaptability, and long-term operational impact. The shift matters. It changes how industries scale without compromise.

Evolution Of Automated Packaging Lines

Early automation solved only basic movement problems. Modern packaging lines now respond, adjust, and learn. Sensors, software logic, and mechanical precision combine into smarter workflows. This evolution allows manufacturers to maintain consistency while managing higher volumes. Downtime reduces. Labor strain drops. Decisions become data-driven. Automation no longer feels optional. It feels necessary. A turning point for competitive production environments.

Role Of Intelligent Robotic Handling

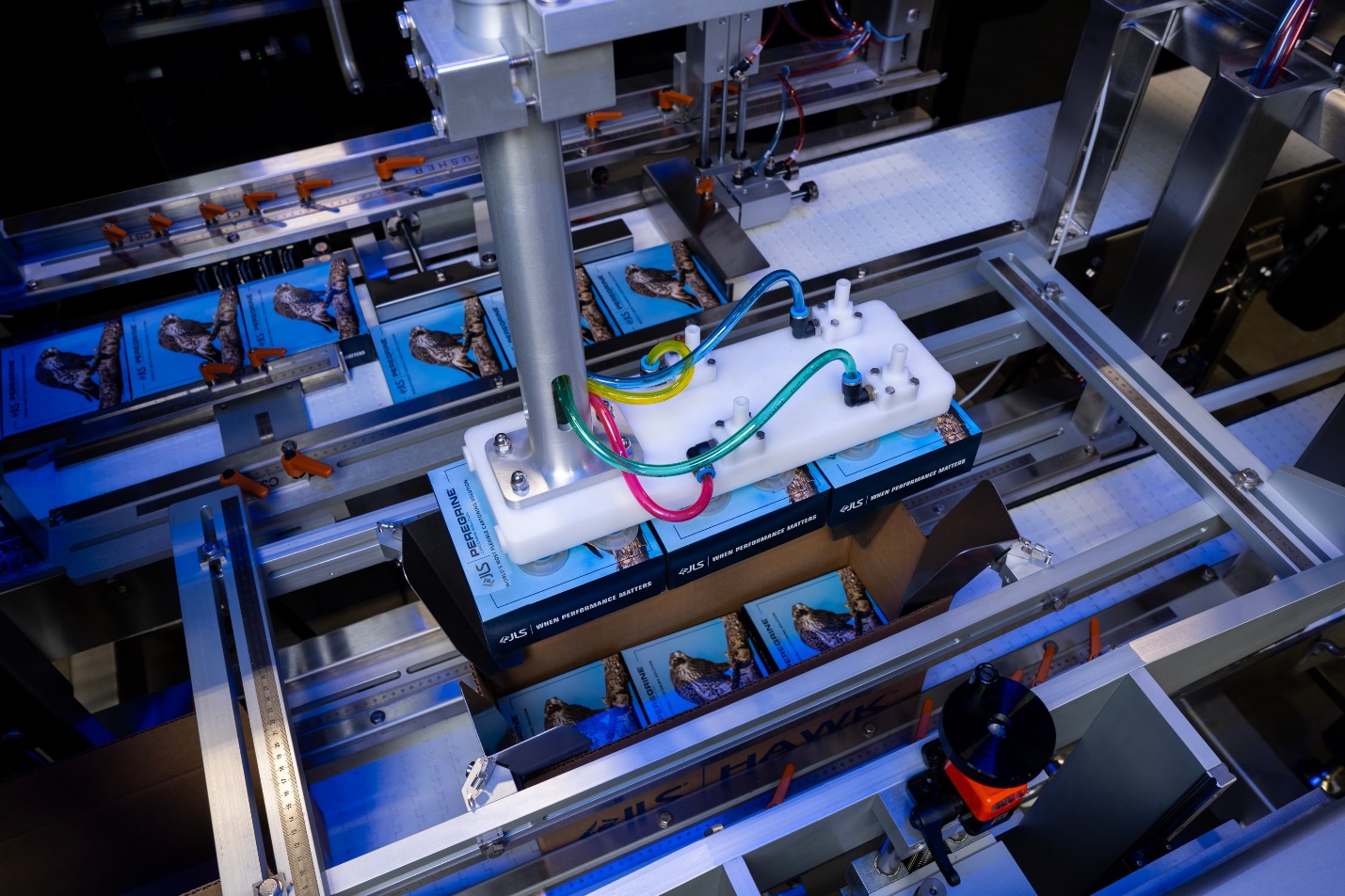

At the center of efficiency sits pick and place robots, engineered for speed and delicate control. These machines transfer products from conveyors to cases with repeatable accuracy. They adapt to varying shapes, weights, and orientations. That flexibility matters, especially in food and consumer goods. Fewer errors occur. Product damage drops. Throughput rises steadily. Quietly effective. Always consistent.

Design Principles Driving System Performance

Packaging systems succeed when design aligns with application needs. Hygienic construction, modular layouts, and intuitive controls define modern solutions. Robotic case packaging systems now integrate vision guidance and safety features without complexity. The design supports quick cleaning and fast changeovers. That matters during multi-SKU operations. Simplicity wins. Efficiency follows. Performance becomes predictable across shifts and seasons.

Impact On Workforce And Operations

Automation reshapes roles rather than removes them entirely. Operators shift from manual lifting to monitoring systems and data flows. Skill requirements evolve. Safety improves significantly. Repetitive injuries decline. Productivity stabilizes. Morale improves, surprisingly. Automated case packaging allows teams to focus on quality and oversight instead of exhaustion. A practical change. Subtle, but powerful.

Scalability Benefits For Growing Manufacturers

Growth introduces pressure. Higher demand exposes inefficiencies fast. Robotic systems scale without dramatic reconfiguration. Adding capacity becomes easier. Case formats change faster. Product launches face fewer delays. Pick and place robots handle expansion smoothly when volumes spike unexpectedly. That adaptability protects margins. Growth feels controlled instead of chaotic. A strong advantage in competitive markets.

Technology Trends Shaping Future Packaging

Software intelligence continues advancing. Predictive maintenance, remote diagnostics, and smarter vision systems redefine reliability. Robotic case packaging systems increasingly connect with upstream processes for synchronized flow. Data becomes actionable. Systems self-adjust. Errors get flagged early. The future looks responsive. Not rigid. Packaging lines transform into intelligent ecosystems rather than isolated machines.

Conclusion

Packaging decisions influence more than logistics. They affect brand trust, delivery timelines, and operational resilience. Pick and place robots and robotic case packaging systems offer precision without fatigue, speed without compromise. Automation supports consistency during uncertainty. That reliability defines modern manufacturing success. The shift is already happening. Quietly. Decisively.