For things like food processing, medications, and chemicals, it is important to supply things accurately to ensure rate and consistency. Volumetric cup fillers and powder fillers are two crucial devices that help you put the proper amount of stuff in containers. These technologies not only make packing faster, but they also make sure that every item fulfills both government regulations and what customers demand. This essay will speak about how useful and vital both filling systems are.

Getting to know volumetric cup fills

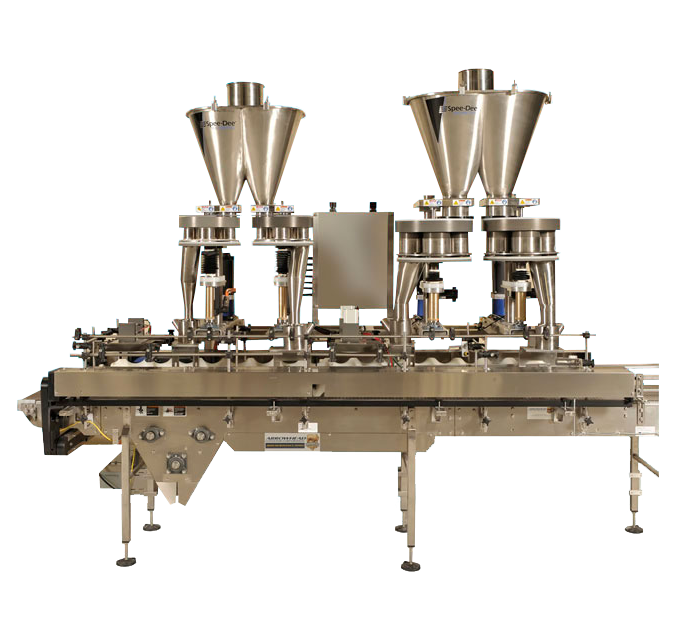

A volumetric cup filler is a type of filling machine that utilizes a cup to measure out a specified amount of material and then puts it into containers. These fillers are very useful in the food sector for items like cereals, snacks, and powders. The nicest part about volumetric cup fillers is that they can provide you with exact volume readings. This makes them great for packaging products that have a constant density. By managing the amount of each cup, these devices help make sure that the packaging procedure is always the same and correct.

How Powder Fillers Work

“Powder fillers” are unique equipment that fill boxes with powdered components. People who work with prescribed drugs, sugar, flour, spices, and other gadgets like that usually use this equipment. It is crucial to be very particular while filling powders so they don’t get overly complete or too empty. This is because of the truth that the powder’s waft may vary. Powder filler use auger structures, vibratory trays, or vacuum technologies to ensure that the powder flows easily and uniformly. To avoid wasting materials and make sure the packing is right, this level of accuracy is highly crucial.

The advantages of volumetric cup fills.

One of the best things about volumetric cup fillers is that they can accomplish a lot of things and do them quickly. These machines are great for production lines that need to fill a bunch of containers quickly and accurately. You may easily modify the size of the cups to include different things because the product’s density and packaging needs can change. Volumetric cup fillers are often the best choice because they are simple to use and don’t need any setup or upkeep. Because of this, they are a good solution for manufacturing lines that are always running.

Powder fillers make it easy to package powder in a precise way.

Powder fillers are the greatest way to fill containers with powdered things since they are so precise. Powder fillers have to think about the varying flow rates and densities of powders, but this isn’t a problem with liquid fillers. Powder fillers can control how much product they give out by utilizing an auger screw or other ways to dispense it. This makes sure that every box has the proper amount of weight or space. Powder fillers help maintain things the same and reduce waste during production, whether it’s for baking supplies or medicine.

How These Fillers Help Packages Work Better

Both powder fillers and volumetric cup fillers speed up the procedure of packaging a lot. These machines fill things automatically, which means less work for human beings and faster manufacturing. They also assist save cash by way of presenting genuine measurements and cutting down on mistakes that cause high-priced overfills or underfills. When groups want to make more of something, those fillers assist them in preserving extraordinary requirements throughout large production batches by making things greater predictable and constant.

Conclusion

Powder fillers and volumetric cup fillers are particularly significant in the packing industry since they are quick, accurate, and work well. These machines make sure that products are filled correctly, which saves on waste and keeps the products’ quality. These technologies are important for many businesses because they help maintain their production lines running smoothly and meet the increased demand for well-packaged items.